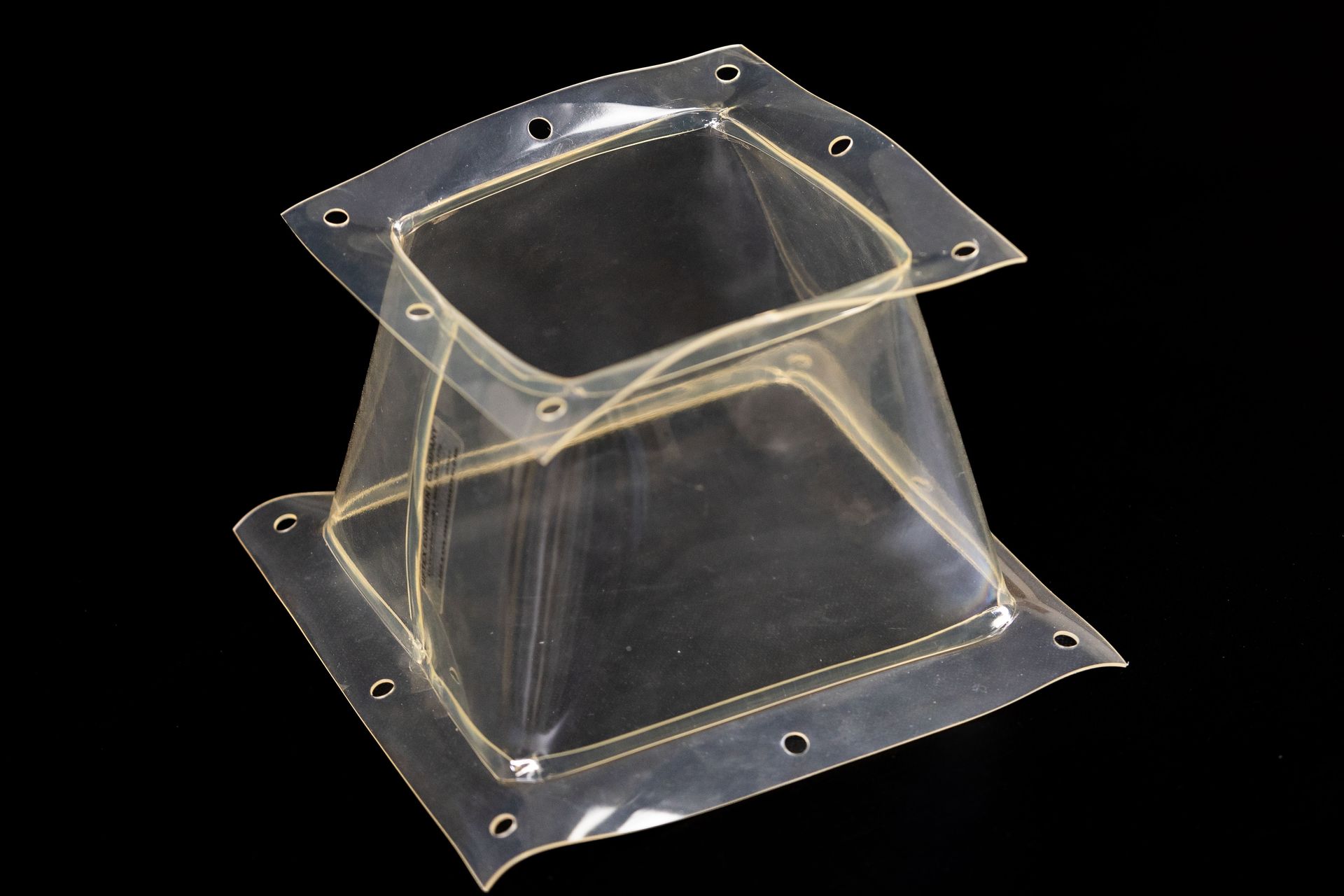

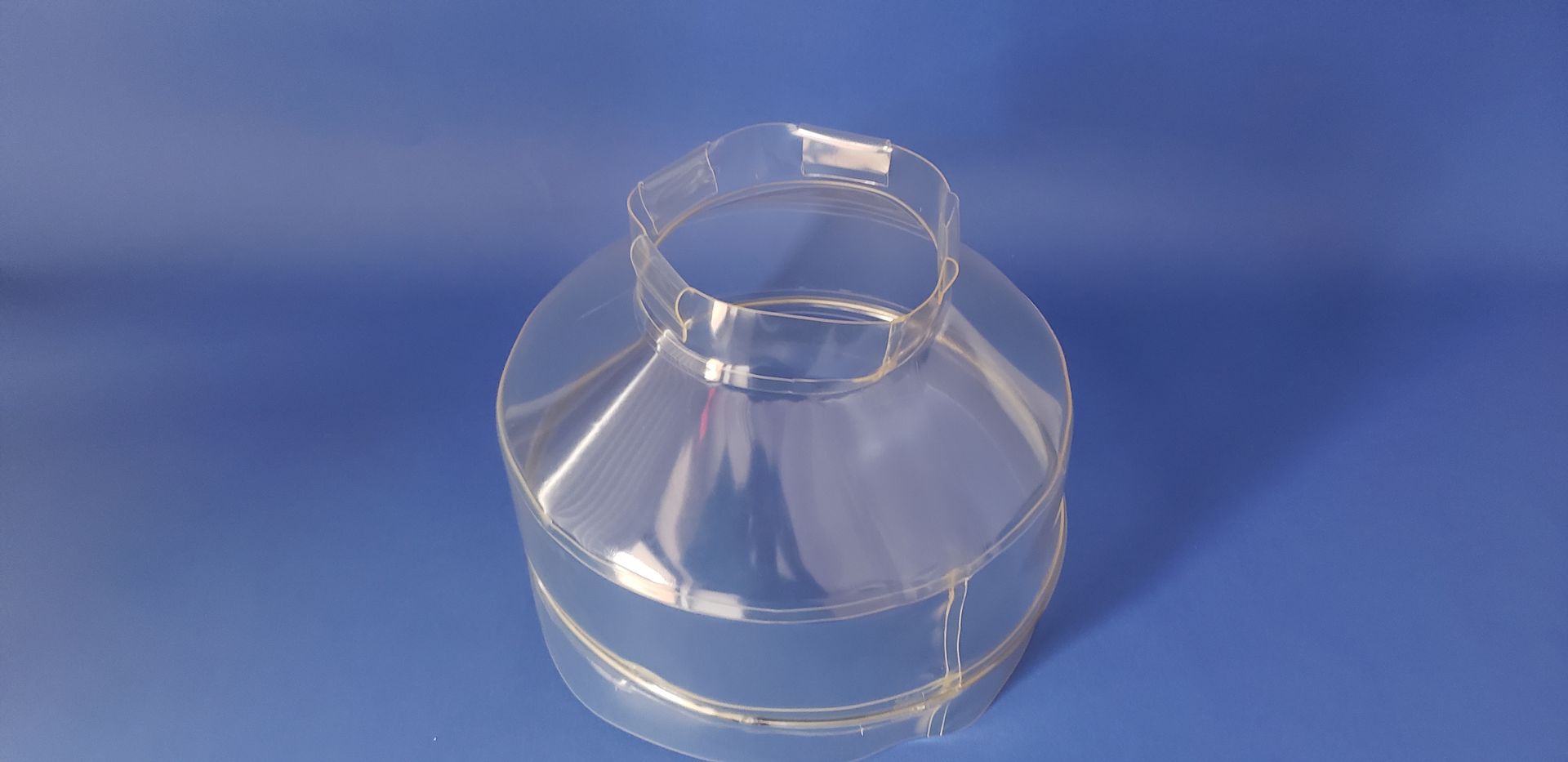

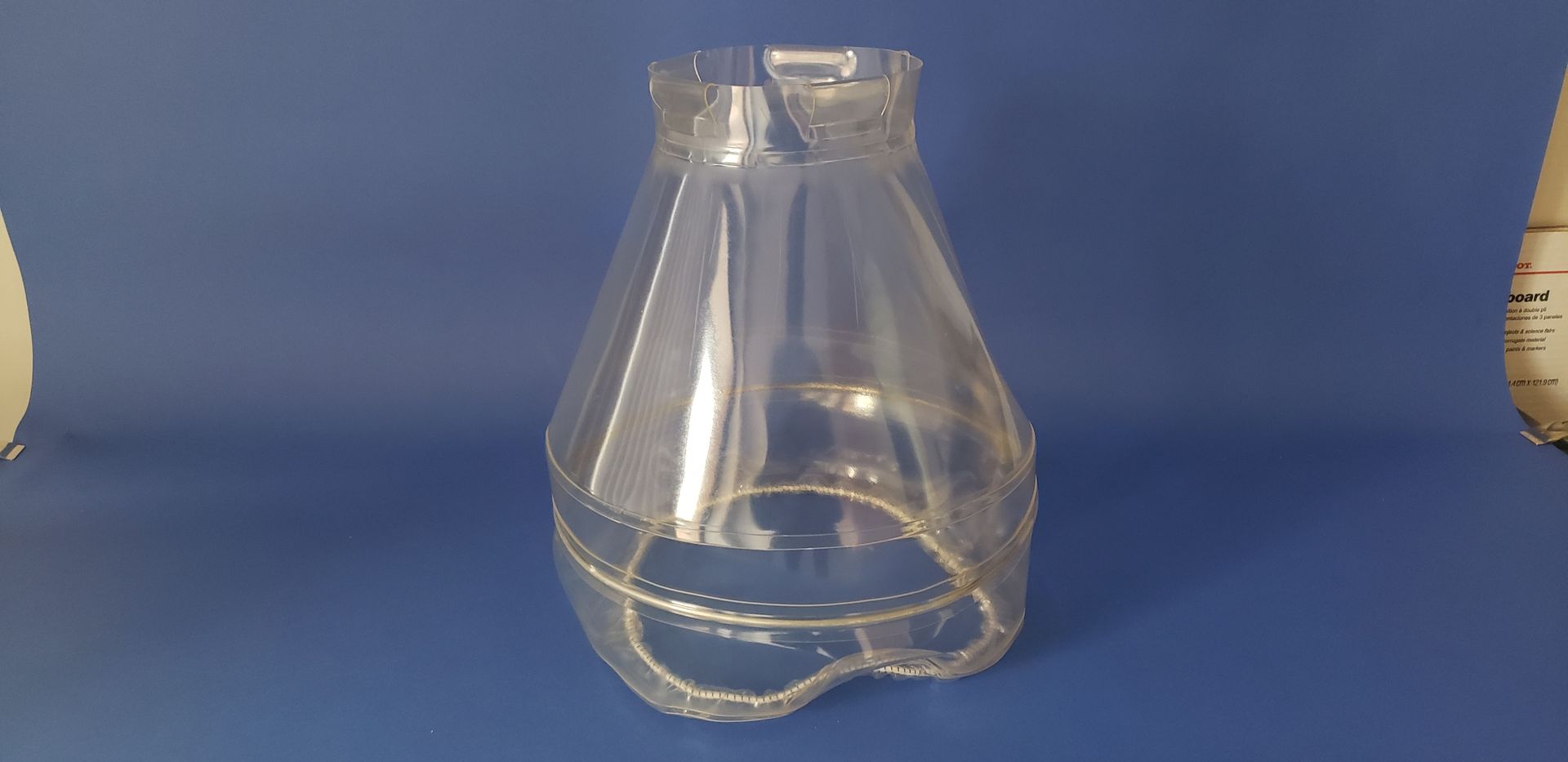

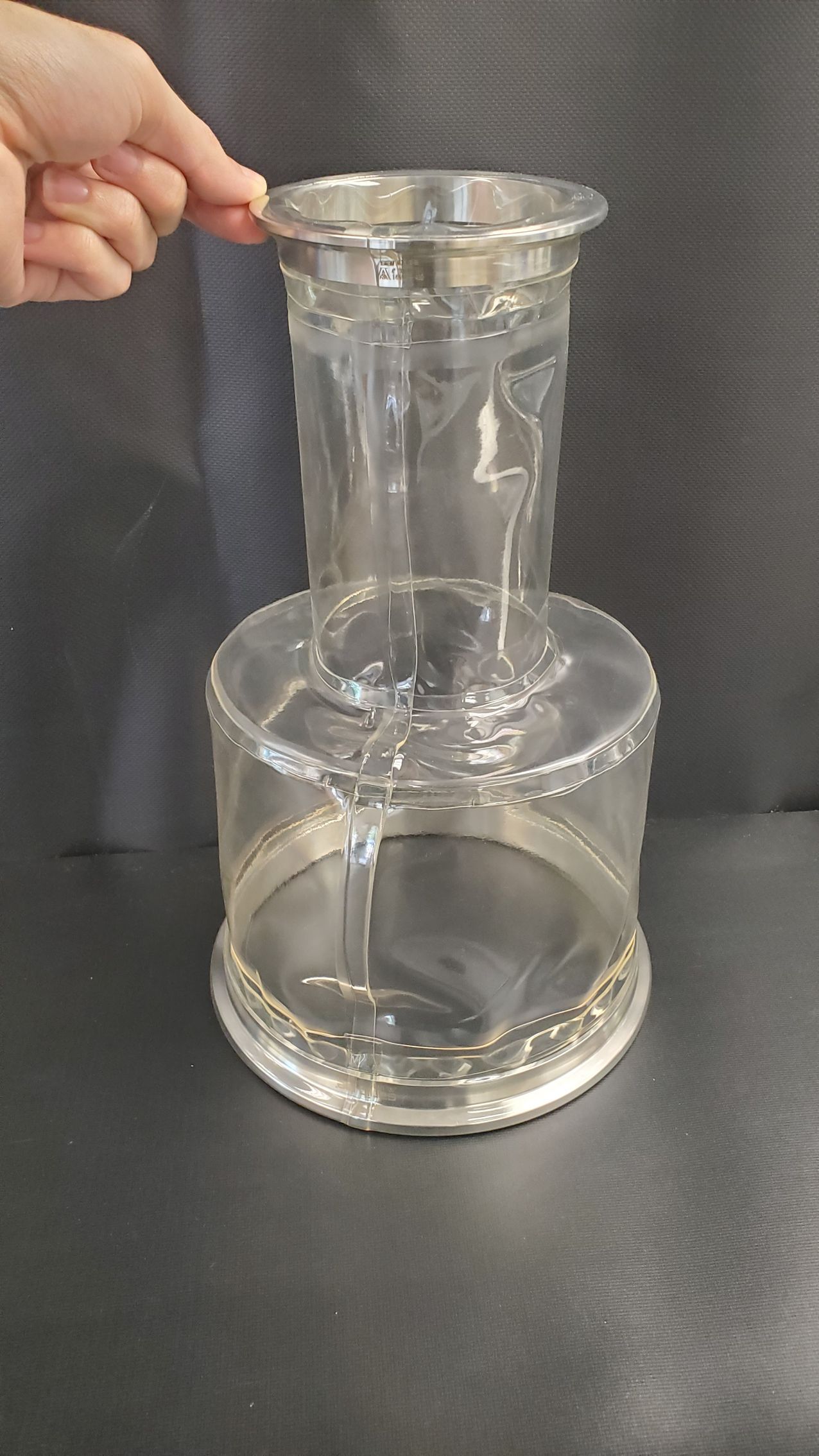

Description:

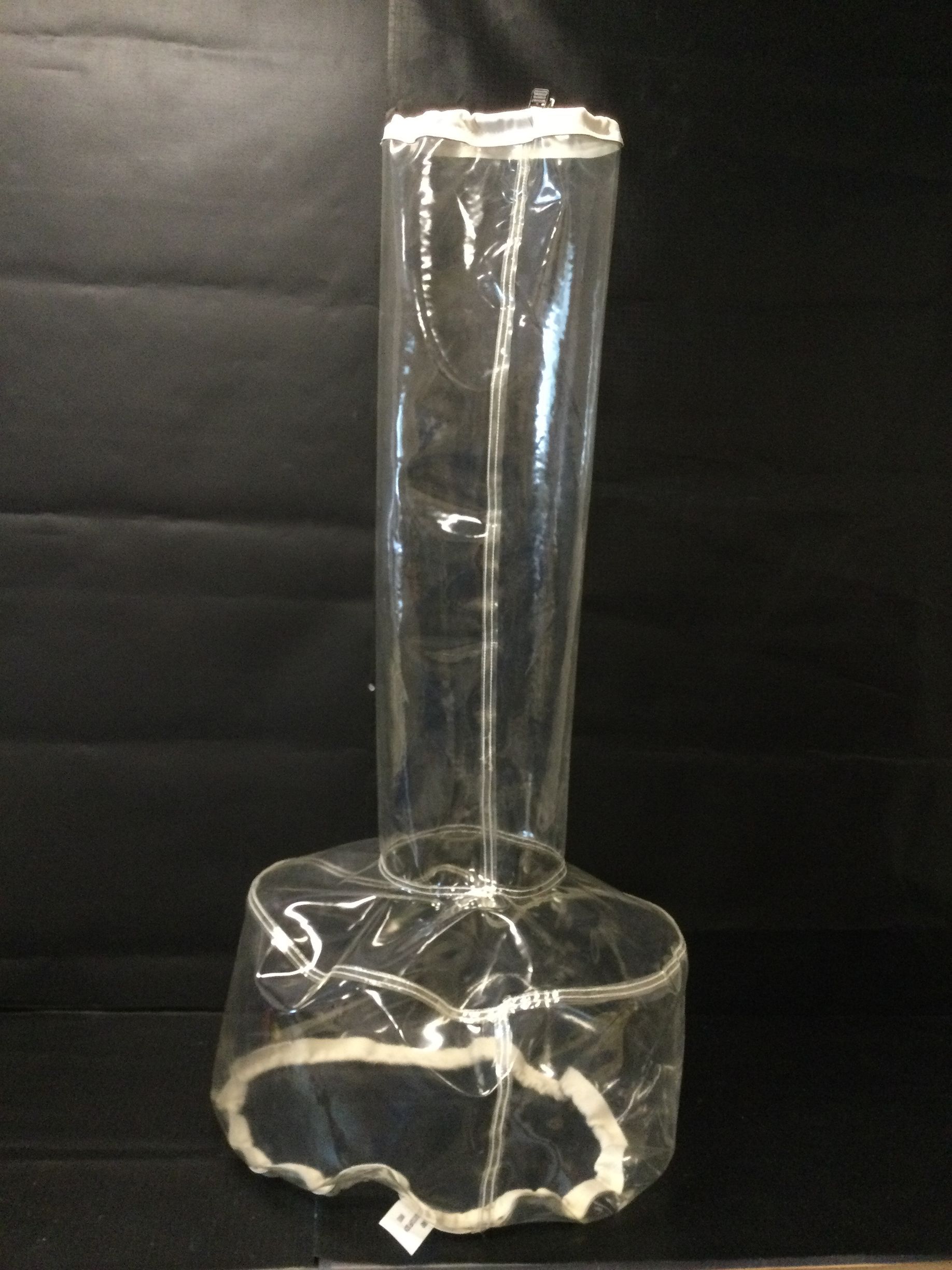

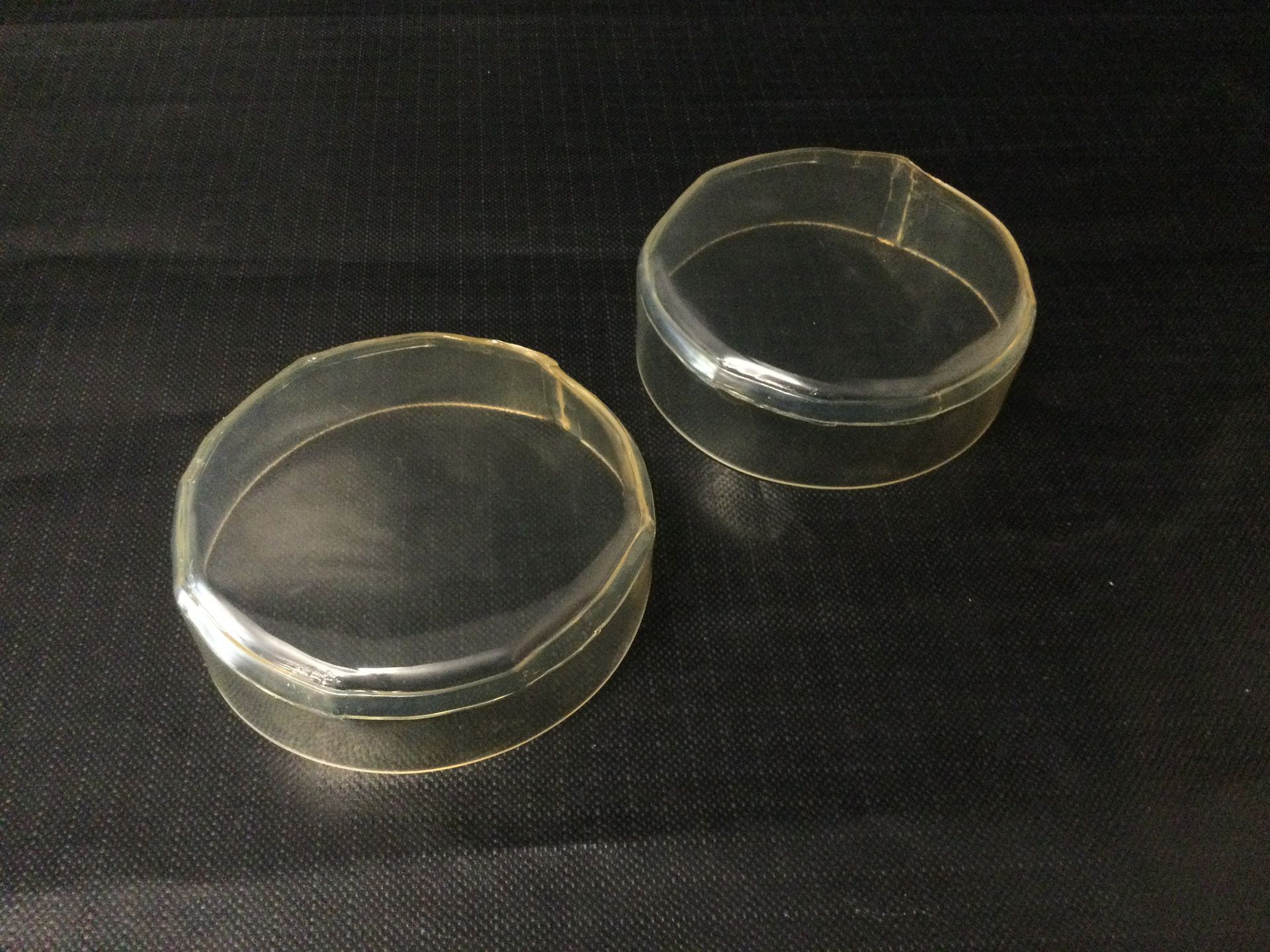

ClearFlex is a static-dissipative polyurethane material that can be sewn or welded into custom connectors for exceptional performance in industrial applications.

Documents and Resources:

For in-depth information on the features of ClearFlex, refer to our detailed documents and resources.

Start Your Custom Project With Us Today

Embark on a journey to innovate and excel with our tailor-made industrial solutions. Connect with our experts now to elevate your operations with customized, precision-engineered products.